Services – Commitment – Results

An overview

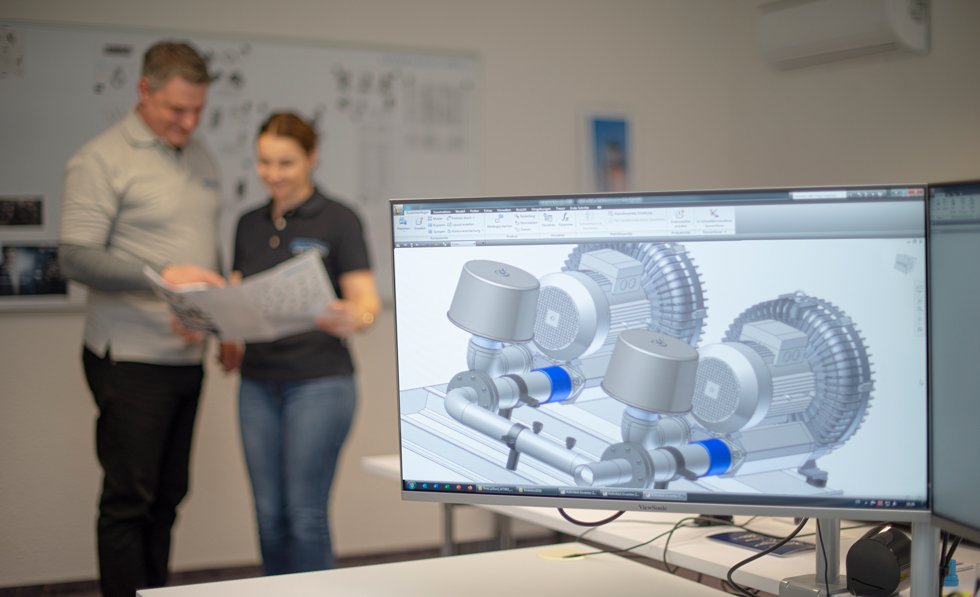

Construction

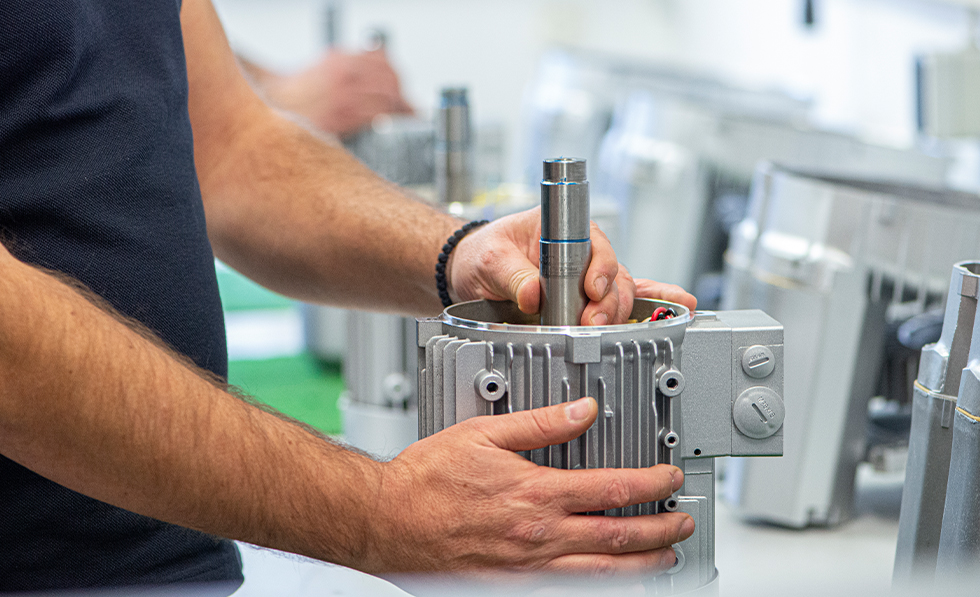

Individual components up to complete assemblies can be integrated into production plants in a customised manner.

Interpretation

Existing plants are reassessed and optimised for efficiency and performance. For new developments Wetravent will find the best solution for your requirements.

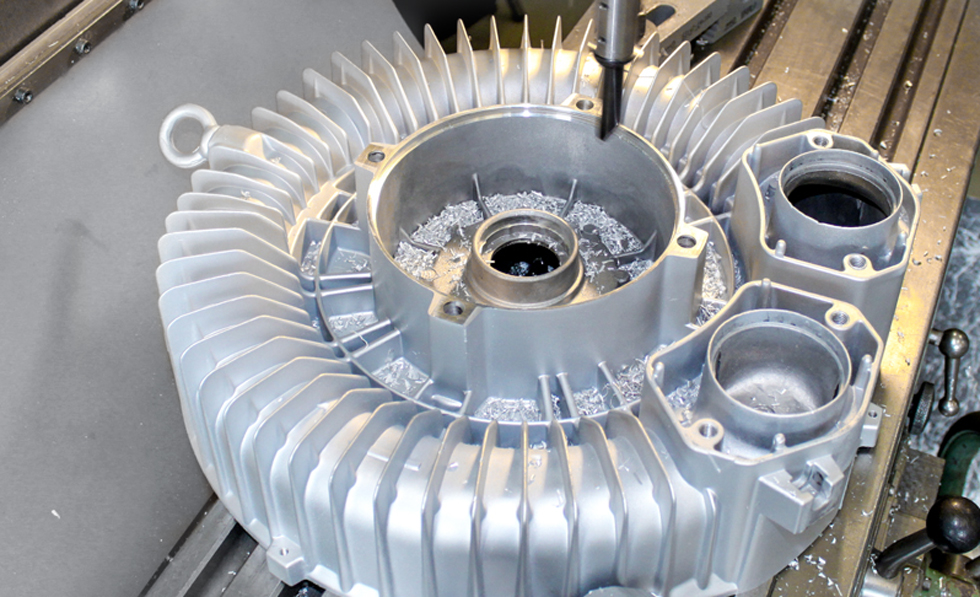

Mechanical manufacturing, sheet metal working, surface treatment

Samples and individual parts can also be produced in series.

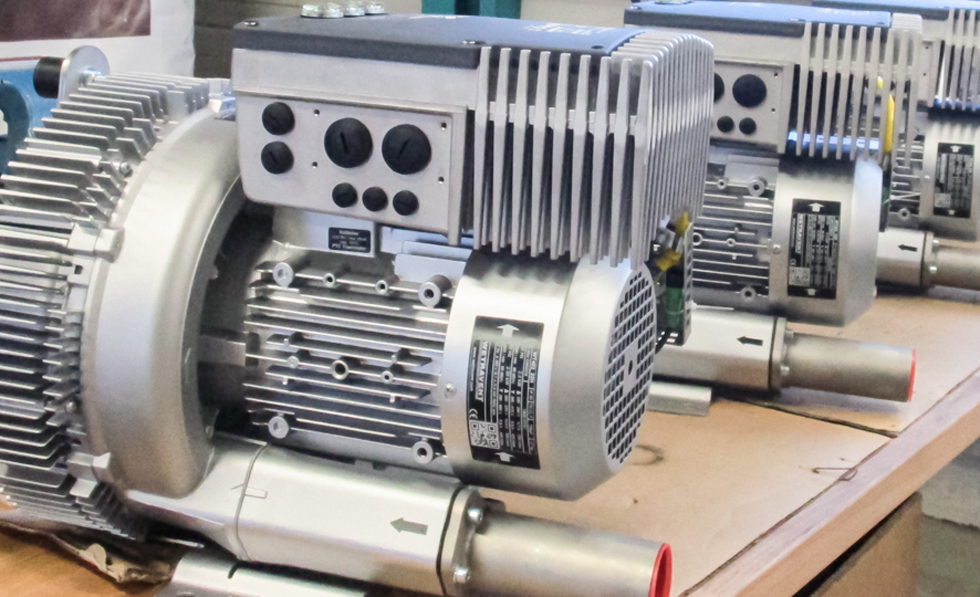

Drive systems

Drive systems are constantly developing and becoming more and more efficient. Wetravent consistently applies this development.

Assembly

Painting

Paint available in all colours.

Final inspection

The use of test equipment at all stages of production, up to 100% testing of all units, ensures perfect functioning even under the toughest operating conditions.

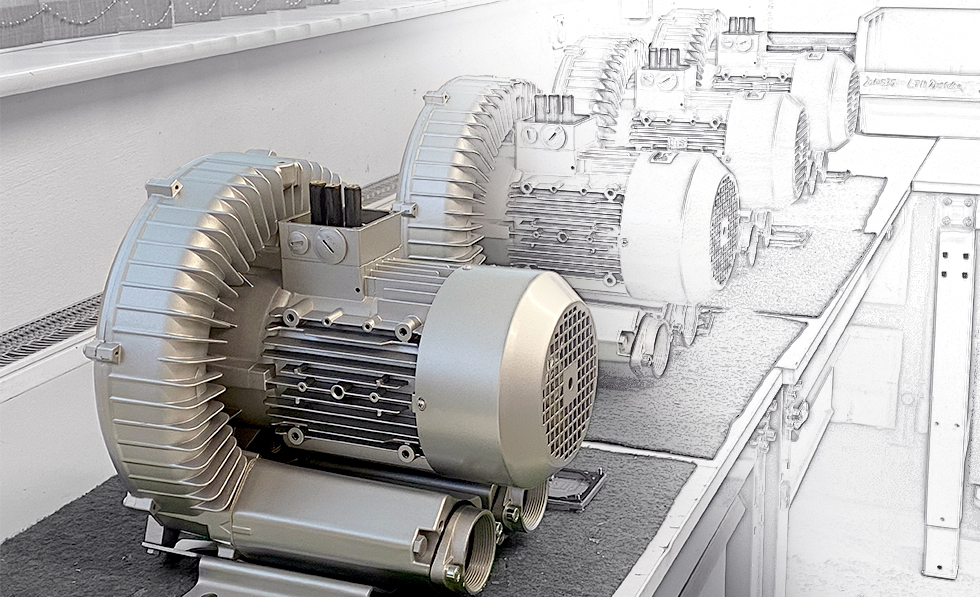

WETRAVENT Manufacture

– Technology Art made with Love –

WETRAVENT realises design ideas. Whether it’s a personal nail dryer, a letterbox or an umbrella stand, ideas are brought to life with customised solutions.

Service – Support – Deployment

WETRAVENT offers customers various additional services. A selection of our services is presented here. Furthermore, there are further services such as our warehousing. In our warehouse in Vaihingen/Enz there is a large number of different spare parts and accessories which can be delivered directly from stock.

Service on site

From design to commissioning we help you on site.

Samples

Retrofit

Trainings

Wetravent employees are always up to date with the latest technology thanks to regular training courses.

We also advise and support our customers’ fitters with training on maintenance and commissioning.

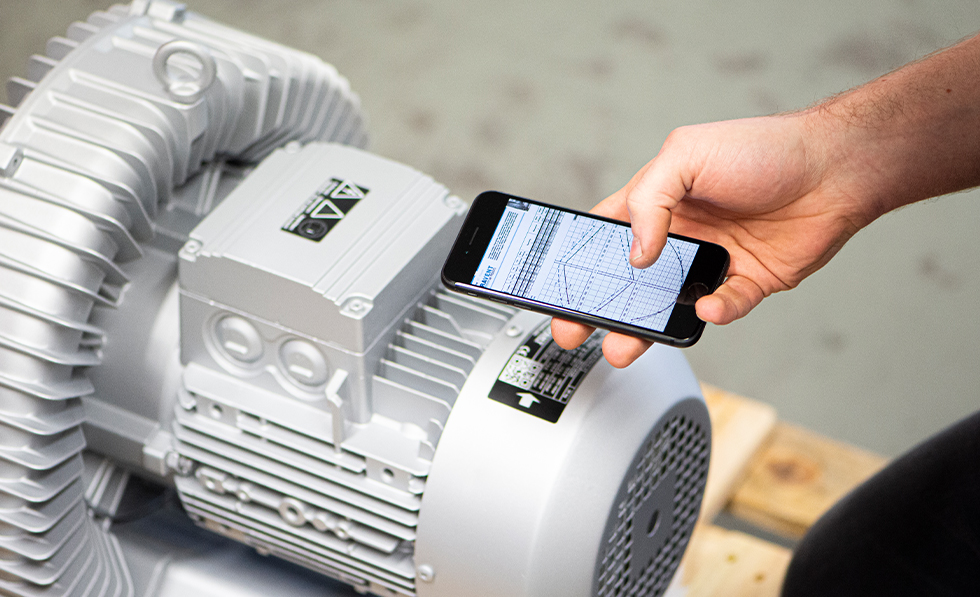

Data retrieval

With the QR code from the type plate directly to the data sheet of the unit!